Pull Compensation in Embroidery for Clean and Accurate Designs

If you have ever stitched a design and noticed that shapes look tight, letters seem thin, or circles turn into ovals, you have already seen why Pull Compensation in Embroidery matters so much. It is one of those small technical steps that makes a big difference in final stitch quality. Many beginners skip it, but professionals never do.

In this guide, we will explain pull compensation in simple words. You will learn what it is, why it happens, how it affects embroidery, and how proper compensation helps you get clean and accurate designs every time.

What Is Pull Compensation in Embroidery?

Pull compensation is an adjustment made during digitizing to fix fabric movement. When an embroidery machine stitches, the fabric pulls inward due to thread tension.

Why Fabric Pulls During Stitching

Fabric pull happens because:

- Thread tightens as stitches form

- Fabric stretches slightly under tension

- Dense stitching increases stress

Without compensation, the design becomes smaller than planned.

How Pull Compensation Works

Pull compensation slightly widens stitch areas in the digitizing stage. This extra width balances the pull that happens during stitching.

Simple Way to Understand It

Think of it like this:

- The fabric pulls in

- Compensation pushes stitches out

- The final result looks correct

It is a smart correction, not a mistake.

Why Pull Compensation Is So Important

Skipping pull compensation can ruin an otherwise good design.

Common Problems Without Compensation

- Thin lettering

- Gaps between fill areas

- Distorted shapes

- Poor logo accuracy

These issues make embroidery look unprofessional.

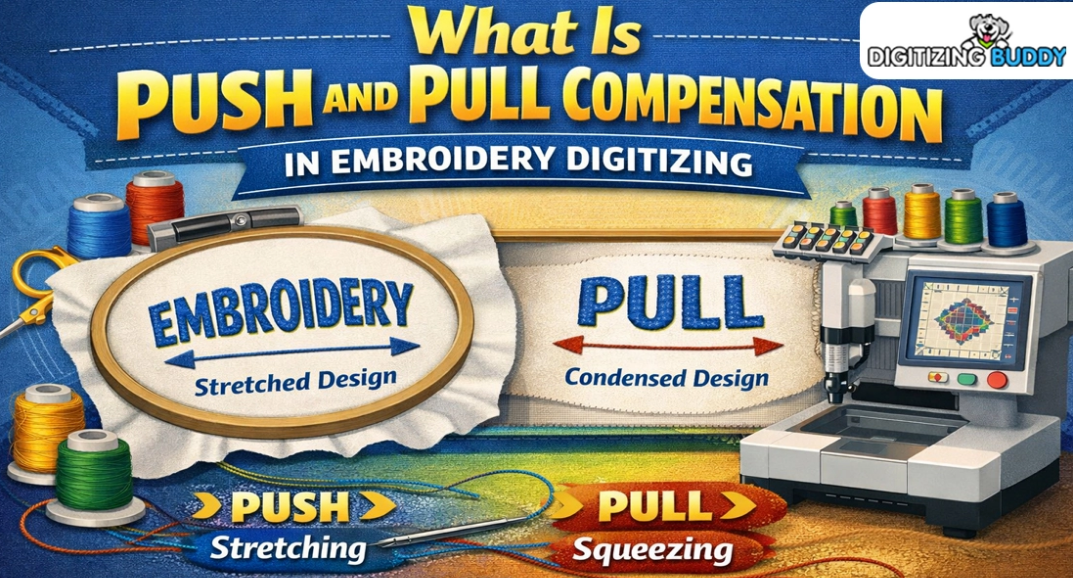

Pull Compensation vs Push Compensation

Many people confuse pull and push compensation.

Key Difference

- Pull compensation fixes inward movement

- Push compensation fixes outward movement

Both work together to keep designs balanced.

What Causes Pull in Embroidery?

Understanding the causes helps you apply the right solution.

Thread Tension

Higher tension pulls fabric inward more strongly.

Stitch Density

Dense stitching increases fabric stress.

Fabric Type

Soft and stretchy fabrics pull more than stiff ones.

Stitch Direction

Long stitches pull more than short stitches.

Fabrics That Need More Pull Compensation

Not all fabrics behave the same.

Stretch Fabrics

T-shirts, polos, and knits need higher compensation.

Lightweight Fabrics

Thin fabrics pull easily under tension.

Caps and Structured Items

Curved surfaces add extra pull stress.

How Much Pull Compensation Is Needed?

There is no one-size rule.

Factors That Affect Amount

- Fabric type

- Stitch type

- Design size

- Thread thickness

Experienced digitizers adjust based on testing.

Pull Compensation for Different Stitch Types

Each stitch reacts differently to tension.

Satin Stitches

Satin stitches need careful compensation to keep columns full.

Fill Stitches

Large fill areas often need less compensation but still need balance.

Running Stitches

These usually need little to no compensation.

Pull Compensation in Small Text

Small text is where mistakes show quickly.

Why Text Needs Special Care

- Letters shrink easily

- Thin strokes disappear

- Gaps appear between characters

Good compensation keeps text readable.

Pull Compensation for Logos

Logos must stay true to shape.

Brand Accuracy Matters

Poor compensation can:

- Change logo proportions

- Damage brand image

- Reduce customer trust

Professional digitizing protects brand identity.

How Digitizers Apply Pull Compensation

Pull compensation is set during digitizing software setup.

Common Methods

- Adjusting stitch width

- Expanding shapes slightly

- Testing on actual fabric

Trial stitching is often used to fine-tune results.

Why Auto-Digitizing Fails at Compensation

Auto tools do not understand fabric behavior.

Limitations of Auto Tools

- No fabric awareness

- Fixed stitch values

- No testing logic

This leads to poor results on real garments.

Signs of Good Pull Compensation

You can spot quality work easily.

What to Look For

- Full satin columns

- Clean edges

- Even spacing

- Correct shape size

The design should match the original artwork.

Signs of Poor Pull Compensation

Bad digitizing shows clear warning signs.

Red Flags

- Thin or broken lines

- Shrinking letters

- Open gaps in fills

- Uneven shapes

These issues often require re-digitizing.

How Pull Compensation Improves Production

Good compensation saves time and money.

Fewer Stitch Errors

Machines run smoother with fewer thread breaks.

Less Waste

Fewer rejected garments.

Faster Output

No need for repeated adjustments.

Pull Compensation for Beginners

Beginners should not ignore this step.

Simple Beginner Tips

- Start with light compensation

- Test stitch on scrap fabric

- Adjust slowly

- Keep notes for future designs

Practice builds confidence.

Testing Pull Compensation Properly

Testing is a key step.

How to Test

- Stitch on the final fabric

- Use correct stabilizer

- Check shape accuracy

- Adjust if needed

Never skip testing for client work.

Pull Compensation and Stabilizers

Stabilizers affect how fabric reacts.

Stabilizer Role

- Strong stabilizers reduce pull

- Weak stabilizers increase pull

Digitizing should match the stabilizer choice.

Common Myths About Pull Compensation

Let’s clear some confusion.

Myth 1: Machines Fix Pull Automatically

Machines follow instructions. They do not adjust designs.

Myth 2: One Setting Works for All

Each design needs its own settings.

Myth 3: Only Large Designs Need It

Small designs need it even more.

Why Professional Digitizing Makes a Difference

Pull compensation is based on experience.

Experience Matters

Professional digitizers:

- Understand fabric behavior

- Adjust for stitch type

- Test designs properly

This leads to consistent quality.

Final Thoughts

Pull compensation is a small adjustment with a big impact. It corrects fabric movement, keeps shapes accurate, and ensures embroidery looks clean and professional. Ignoring it leads to thin stitches and distorted designs. Whether you are stitching logos, text, or detailed artwork, proper pull compensation helps you achieve reliable results. For expertly digitized designs that stitch cleanly on real fabric, many embroiderers rely on the experience and quality standards of Digitizing Buddy.

Post Comment